Chưa có sản phẩm trong giỏ hàng.

HỖ TRỢ, Tin tức công nghệ

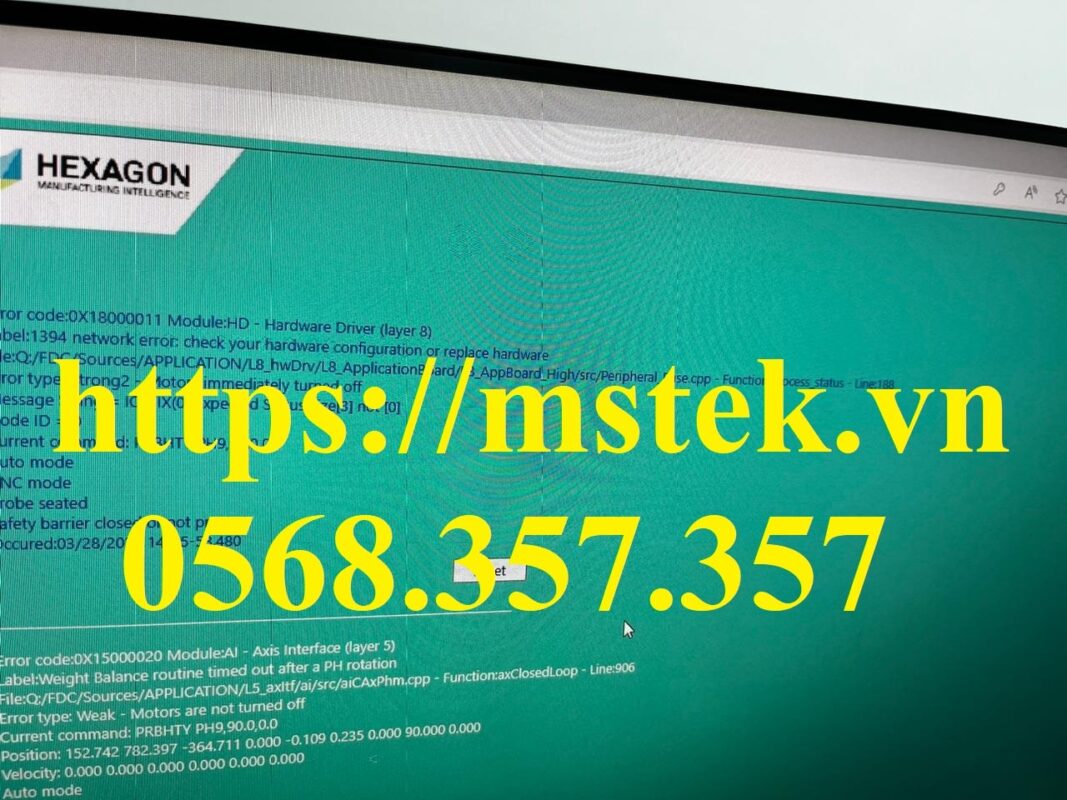

Danh sách lỗi máy CMM Hexagon Error list – Cách khắc phục sửa chữa – Phần 3

Hexagon CMM là thương hiệu hàng đầu trên thế giới.

Máy CMM Hexagon được sử dụng khá phổ biến tại Việt Nam.

Mstek cung cấp cho quý vị thông tin lỗi máy CMM sửa dụng bộ điều khiển: DC240/DC241 DC241ETH//DC800/DC800ETH/RC1/DC4000/H3C-T

Dưới đây là Danh sách lỗi máy CMM Hexagon Error list – Cách khắc phục sửa chữa:

Command Executor (layer 4) 0x14000001 :

| 0x14000001 | System Error calling a RTOS function. |

| 0x14000003 | System Error creating a CE mutex. |

| 0x14000005 | System Error creating CE task. |

| 0x14000008 | System error: Null pointer received. |

| 0x1400000F | System Error calling a list library function. |

| 0x14000010 | System error: failure writing in a list. |

| 0x14000011 | Wrong command status to execute cmd. |

| 0x14000012 | The host sent a STOP command. |

| 0x14000013 | System error: command object not initialized. |

| 0x14000014 | Protocol authorization violation. |

| 0x14000015 | System error: CE invalid RECEIVE status. |

| 0x14000016 | System error: CE invalid EXECUTE status. |

| 0x14000017 | Command not executable in current CE Status. |

| 0x14000018 | Secondary executors not usable for this operation. |

| 0x14000019 | System error: invalid number of executors to be initialized. |

| 0x1400001A | Error detected during init sequence. See errlog in ramdisk.. |

| 0x1400001B | Command not supported. |

| 0x1400001C | System Error: failure initializing the commands attribute. |

| 0x1400001D | System Error: failure unlocking a CE semaphore. |

| 0x1400001E | System Error: wrong status task. |

| 0x1400001F | System Error: CE is detected in deadlock. |

Command Executor (layer 4) 0x14000020 :

| 0x14000020 | System error: failure during command split. |

| 0x14000021 | System Error: invalid case in switch statement. |

| 0x14000022 | Protocol authorization needed. |

| 0x14000023 | AUTO-ADJUSTMENT not enabled. |

| 0x14000024 | Failure reading the adjustment buffer. |

| 0x14000025 | Failure writing the adjustment buffer. |

| 0x14000026 | Commands input buffer overrun. |

| 0x14000027 | Command argument missing or invalid. |

| 0x14000028 | Error setting a parameter value. |

| 0x14000029 | Invalid configuration for the homing sequence. |

| 0x1400002A | Too many internally interpolated points for the HSS movement. |

| 0x1400002B | HSS nominal points not available from the hosts. |

| 0x1400002C | The homing procedure has not been done. |

| 0x1400002D | System Error: wrong clock counter during CE-AI data transfer. |

| 0x1400002E | Command not allowed being the current mode JOG or NULLING. |

| 0x1400002F | Invalid move command: linear axes and indexable wrist cannot move at the same time. |

Command Executor (layer 4) 0x1400003x :

| 0x14000030 | Probe type not valid for the commanded operation. |

| 0x14000031 | Probe hit not occured within the probing limit. |

| 0x14000032 | Probe deflection during a CNC movement. |

| 0x14000033 | Probe unseated after the retract movement. |

| 0x14000034 | Command argument out of limit. |

| 0x14000035 | Invalid reading of the measured point. |

| 0x14000036 | The center for the circular movement is not defined. |

| 0x14000037 | System error submitting a function to the Low Priority Task. |

| 0x14000038 | Circular movement angle is invalid. |

| 0x14000039 | Circular movement distance is too little. |

| 0x1400003A | System error pushing a point in an internal buffer. |

| 0x1400003B | Circular movement cannot start from the circle center. |

| 0x1400003C | Circular movement cannot end to the circle center. |

| 0x1400003D | Invalid low-level matrix. |

| 0x1400003E | System error: cannot get a valid entry for PointInGenOutStruct. |

| 0x1400003F | Weight Balance routine timed out. |

Command Executor (layer 4) 0x1400004x :

| 0x14000040 | E-Stop Push Button Pressed. |

| 0x14000041 | Air pressure is low. |

| 0x14000042 | System error: HW request overlap. |

| 0x14000043 | Power circuit failure. |

| 0x14000044 | CL scan direction not defined. |

| 0x14000045 | Cylindrical scan cannot start on the centerline of the cylinder. |

| 0x14000046 | Cylindrical scan cannot have the direction on the centerline of cylinder. |

| 0x14000047 | CL scan start and direction points too near. |

| 0x14000048 | CL scan direction invalid: start and direction points parallel to surface normal. |

| 0x14000049 | End key pressed. |

| 0x1400004A | Workpiece contact lost during CL scan. |

| 0x1400004B | Timeout occured during Centering operation. |

| 0x1400004C | Centering start and direction points too near. |

| 0x1400?04D | Position out of the machine stroke limit. |

| 0x1400?04E | Feed reduction or ENABLE button from jogbox not allowed |

| 0x1400?04F | The host sent an ABORT command. |

Command Executor (layer 4) 0x1400005x :

| 0x1400?050 | Probe not ready: need Weight Balance. |

| 0x1400?051 | Excessive probe deflection. |

| 0x1400?052 | Axes are standing and wait trigger signal to complete the probe sequence. |

| 0x1400?053 | Trigger Point not occured. |

| 0x1400?054 | Bearing air pressure is low. |

| 0x1400?055 | Probe deflected during a CNC movement and reseated at the end of braking. |

| 0x1400?056 | Map file not present or error in reading map file. |

| 0x1400?057 | Length of authorization code incorrect or missing code. |

| 0x1400?058 | Invalid authorization code. |

| 0x1400?059 | System Error: impossible to get informations on lock map settings. |

| 0x1400?05A | System Error: error during the reading of lock map settings. |

| 0x1400?05B | Map file already locked. |

| 0x1400?05C | MAN/AUTO selector invalid reading. |

| 0x1400?05D | MAN/AUTO selector switch while the machine is moving. |

| 0x1400?05E | Probe collision. |

| 0x1400?05F | E-Stop Push Button Pressed (Auxiliary). |

Command Executor (layer 4) 0x1400006x :

| 0x1400?060 | Brake activated due to a strong emergency. |

| 0x1400?061 | The tempCompType parameter must be set before using the temperature compensation. |

| .0x1400?062 | Machine stop by user. |

| 0x1400?063 | The host sent a STOP command without output error string. |

| 0x1400?064 | Safety barrier violation. |

| 0x1400?065 | Hardware failure of the safety circuitry. |

| 0x1400?066 | Invalid jogShift parameter. |

| 0x1400?067 | Timeout occured waiting for the axes standing (TESTPOS command). |

| 0x1400?068 | System Error: Invalid signal Enum for Scaletune. |

| 0x1400?069 | System Error: invalid Axis ID. |

| 0x1400?06A | System Error: unsupported Hardware Request value. |

| 0x1400?06B | Panel or jogbox button detected during the init. |

| 0x1400?06C | Circular movement start radius and end radius difference too big. |

| 0x1400?06D | Probe reseated at the end of PROBE braking after 3 attempts. |

| 0x1400?06E | Invalid command. Check weightCompType parameter. |

| 0x1400?06F | Invalid command. Check volCompType parameter. |

Command Executor (layer 4) 0x1400007x :

| 0x1400?070 | Invalid command. Weight compensation not available.. |

| 0x1400?071 | Invalid jogLock parameter. |

| 0x1400?072 | Invalid jogShiftLock parameter. |

| 0x1400?073 | Detected movement crossing virtual forbidden area. |

| 0x1400?074 | Detected movement inside virtual forbidden area. |

| 0x1400?075 | Data entered for MinVol or MaxVol are not correct. |

| 0x1400?076 | Command cannot be executed because the motors are off. |

| 0x1400?077 | Motor off commanded by Energy Saver. |

| 0x1400?078 | Missing input definition for a non-integrated limit switch. |

| 0x1400?079 | Data entered for MinStrokeSlowZone or MaxStrokeSlowZone are not correct. |

| 0x1400?07A | Data entered for MinStrokeSlowZone or MaxStrokeSlowZone out of range. |

| 0x1400?07B | System Error in LPT. |

| 0x1400?07C | Error in transducer reference mark position. |

| 0x1400?07D | Machine crash detected. |

| 0x1400?07E | Centering evaluation not possible. |

| 0x1400?07F | Wrist yaw circuit failure. |

Command Executor (layer 4) 0x1400007x :

| 0x1400?080 | File not present or error in reading. |

| 0x1400?081 | Eco Mode + circuit failure. |

| 0x1400?082 | Probe unseated after the auto retract movement. |

| 0x1400?083 | MEMO: EcoMode + license is required. |

| 0x1400?084 | MEMO: new FDC installed, check if a license is needed. |

| 0x1400?085 | MEMO: temporary license has expired. |

| 0x1400?086 | License is required to activate Scan Pilot Retrofit. |

| 0x1400?087 | Scan Pilot Retrofit is already enabled. |

| 0x1400?088 | modelID parameter has an invalid value for Scan Pilot Retrofit. |

| 0x1400?089 | DSP version and s1Vel are not consistent. |

| 0x1400?08A | Cabinet Over Temperature. |

| 0x1400?08B | Other arm of DUAL ARM system is in strong error. |

| 0x1400?08C | First Reference mark not found where expected. |

| 0x1400?08D | THD Probe not ready.. |

| 0x1400?08E | Invalid configuration for the pre-homing sequence. |

| 0x1400?08F | Other arm of DUAL ARM system is in weak error. |

| 0x1400?090 | License required to execute this command. |

| 0x1400?091 | Problem on DUAL ARM error input: please check settings/cables on system arm1 & arm2. |

| 0x1400?092 | Problem on DUAL ARM selector input: change setting SINGLE/DUAL arm not allowed. |

| 0x1400?093 | DSP version must be 3.1 or higher for this machine. |